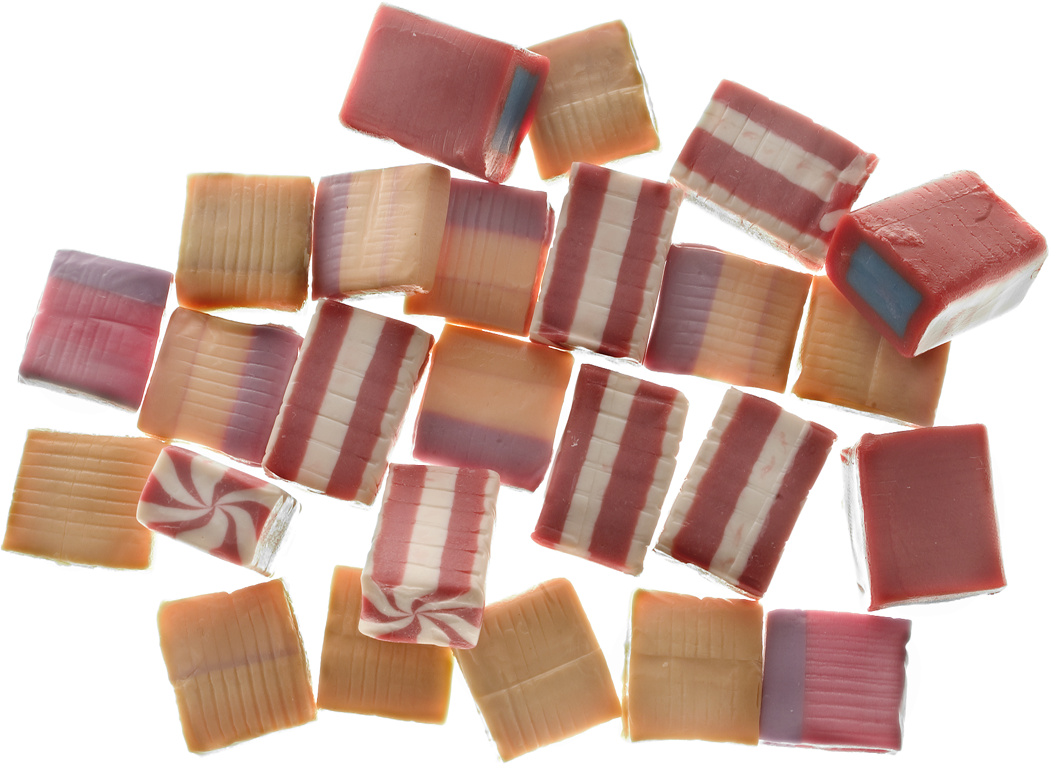

Chewy Candy

S-31 GUM AND CHEW FORMING

(with center filled capabilities)

The S-31 forming system has been developed for the production of filled soft products. A special extrusion head and filling pump for granular or sherbet type fillings is also an option available.

S-34 CO-EXTRUDER AND COOLING

This extrusion and cooling line is designed for feeding either low or high speed 'cut and wrap' machines. The extruder can be provided to handle up to 12 ropes at once as well as 2-3 colors and flavors depending on size and capacity.

S-37 Chewy Centers Line

This drop roller line supplied with a pair of forming cylinders can be altered with ease in order to produce several different shapes.

Features:

Chewy, caramel or croquant centers forming and cooling line excellent for sugar or chocolate coated products.

Three models for small, medium and high capacity from 300, 600 and 1.000 kg per hour production.

Hygienic design with easy change from one shape to another with forming rollers and frame removable by carrier.

User friendly PLC with touch screen control for storage and re-call of the setting parameters.

Creative and original shapes are also possible.

Cooling system hygienic, efficient with CIP (clean in place) option, possibility to adjust cooling power in different zones of the process.

Output per hour:

300-1000kg

S-39 Rolling and Scoring Line

The S-39 rolling and scoring line has been developed using the same platform as the S-37 for production of sticks, pellet chewing gum, bubble gum and sugar free gum.

Output per hour:

200-600kg